Industrial Automation Solutions, Services & parts

Every industry has its own unique requirements and challenges. That’s why we offer customized automation solutions and components tailored to fit your specific needs.

Plant Automation to Make You Smile

We provide North American manufacturing companies with industrial automation parts and solutions in thermal & fluid processes, web handling, robotics, industry 4.0, safety and control panels.

Web Handling

We will work with your company to design, build and maintain optimal-control web handling systems.

Robotics

We offer quick ROI and quick changeover. We provide a fully integrated robotic solution that addresses your issue.

Industry 4.0

We provide both product and expertise when it comes to integrating plant intelligence solutions.

Thermal & Fluid

We are your go-to place for heaters, temperature controllers, pressure transducers, electric heaters, sensors, thermocouples / RTDs, and transmitters.

Safety

We are at the forefront of factory automation and plant safety. From light curtains to E-Stop, we have you covered.

Control Panels

Our team excels in delivering comprehensive, expert UL 508a certified control panel design and assembly solutions.

Why Choose Sure Controls?

We keep your operation running, growing and innovating

Calibrations

Correct small problems before they become big and expensive. Keep equipment and processes within the manufacturer’s specs, and reduce scrap and unwanted downtime. NIST traceable.

Design Solutions

At Sure Controls, we design automation solutions with the entire process in mind. This sets the stage for getting every design detail right. Talk to us about challenges or future projects you have. We provide smart economical designs that stand the test of time.

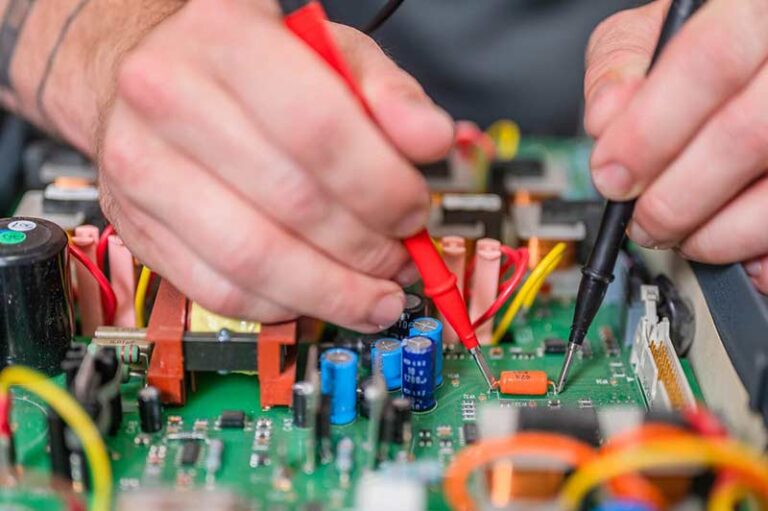

Repair

Should you repair or replace? Our automation solutions take all options into account. Let us help you make the best decision for your business. We will work with you to assess short-term cost as well as long-term viability.

In-Stock, Readily Available Parts

Need an off-the-shelf or a hard-to-find part? Sure Controls has automation parts on hand for quick turn-around. Let us help you make the best choice for your business. We aim to leave you smiling.

Plant Automation to Make You Smile!

Control Panel Experts

Efficiently Monitor, Protect and Control

We bring over 40 of years experience in designing new control panels and refurbishing existing ones. Our team excels in delivering comprehensive, expert control panel design and assembly solutions.

We take pride in using readily available components that can be easily replaced, thereby reducing maintenance costs. Our control panel designs and assemblies feature UL 508a or CSA, compliant panel construction, ensuring that they meet rigorous safety standards.

Moreover, our control panels are meticulously designed to optimize functionality, minimize energy consumption, and lower operational expenses. With our solutions, your manufacturing facility can operate at its peak performance.

Sure Controls Locations

Woods Edge Innovation Center

Our team of engineers and technicians provide automation solutions to optimize your operation - increasing efficiency and reducing downtime.

Tower View Distribution Center

Having trouble sourcing components? Our team of experts are available to assist! We make sure you have the right part at the right time for your custom application.

Hear From Sure Controls Customers Themselves!

“One of the main reasons we decided to work with Sure Controls is because they are highly responsive. If there’s questions, they are right there to answer them. They’re local and a great group to work with.”

- Mark Clauss

Process Control Manager at Pioneer Metal Finishing

“I can’t thank you guys enough for your time and efforts on this project. We had quite a few things that caused us headaches, but everyone is very pleased with the project and your work. Thank you and I look forward to working on the next phases of the project with you.”

- Garret Yohnk

Senior Manufacturing Engineer at Darley

“I want to thank the team at Sure Controls for their great work on this project. They were easy to work with, bright with ideas, willing to make improvements rather than just recreate the wheel, and punctual to the schedule in a very difficult supply chain.”

- Bob Reeves

Operations Director at Kaysun

What's Trending?

The Latest from the Sure Controls Blog

The manufacturing industry is constantly evolving and staying informed about the latest trends, technologies, and regulations can give you a competitive edge.

Case Studies

See What Our Clients Have to Say

Hear what our customers are saying about us. Check out our case studies for examples of how Sure Controls delivers reliable and innovative automation solutions.

Our Associations