In today’s fast-moving world of logistics and supply chain management, efficiency is no longer just a goal—it’s a requirement. Customer expectations for faster delivery, customized products, and seamless service continue to rise. To meet these challenges, many companies are turning to Autonomous Mobile Robots (AMRs) as the next big step in logistics innovation.

Why AMRs Are a Game-Changer

Unlike traditional conveyor systems or Automated Guided Vehicles (AGVs) that rely on fixed paths, AMRs use advanced sensors, cameras, and AI to navigate dynamic environments. This flexibility makes them ideal for warehouses, distribution centers, and manufacturing facilities where layouts and workflows frequently change.

Key benefits include:

- Scalability: AMRs can easily be added or reprogrammed as demand grows or shifts.

- Safety: Built-in sensors help prevent collisions with people or equipment.

- Productivity: By handling repetitive material movements, AMRs free workers to focus on higher-value tasks.

- Flexibility: They adapt to new routes, inventory changes, or unexpected obstacles with minimal downtime.

The Future of Logistics with AMRs

The role of AMRs is expected to expand as technology advances and supply chain demands grow more complex. Here are three trends shaping the future:

- Collaboration Between Humans and Robots

AMRs won’t replace people—they’ll complement them. Expect to see more workflows where AMRs handle transportation tasks while humans focus on decision-making, customer service, or quality control. - Integration with AI and IoT

Future AMRs will connect seamlessly with warehouse management systems (WMS), enterprise resource planning (ERP) tools, and IoT-enabled equipment. This will enable real-time optimization of routes, inventory management, and predictive maintenance. - Industry-Wide Adoption

From e-commerce giants to mid-sized manufacturers, AMRs are becoming accessible to more organizations. As costs decrease and capabilities increase, AMRs will shift from “nice-to-have” to “must-have” for staying competitive.

Boosting ROI with AMRs

Like any technology investment, the return on investment (ROI) for AMRs depends on smart planning and execution. Here are a few strategies to maximize ROI:

- Start with High-Impact Workflows: Focus on tasks with high labor costs or frequent bottlenecks, such as material transport between work cells or moving goods to shipping.

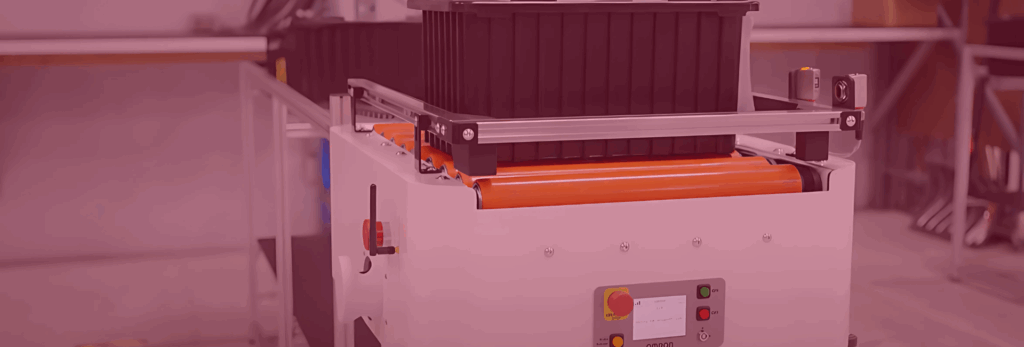

- Leverage Modular Toppers: Choose AMRs that support interchangeable toppers (roller decks, lift modules, conveyors) to increase versatility and reduce the need for multiple robot types.

- Integrate with Existing Systems: Connecting AMRs to your WMS or ERP allows for better scheduling, real-time tracking, and reduced downtime.

- Measure and Iterate: Track key metrics—cycle time, throughput, error rates, and labor hours saved—to evaluate performance and identify opportunities to expand.

- Scale Strategically: Prove ROI with a pilot program before rolling out across your operation. Scaling in phases helps balance costs with results.

At Sure Controls, we’re helping manufacturers rethink material movement with intelligent, agile, and scalable solutions that:

✅ Navigate around obstacles and people

✅ Perform multi-location drop-offs

✅ Increase safety and reduce labor strain

✅ Adapt as your facility grows

We’ve recently deployed AMRs with custom toppers—from roller beds to bins—to streamline everything from part delivery to finished goods handling.

Bottom line: AMRs aren’t just the future of logistics—they’re reshaping it right now. With the right approach, companies can maximize ROI while building a smarter, more resilient supply chain.

Curious about how AMRs can benefit your operation? Let’s connect.