Capillary Dies in Capillary Rheometer

Azadeh Farahanchi, Rheological Scientist, Ph.D

05.21.2018

Capillary rheometer is one the most common melt rheometer techniques to understand flow behavior and rheological properties of polymer materials under typical processing condition. In this test method, the molten polymer sample is forced to flow through an interchangeable capillary die by means of a piston. The piston moves down at various speeds and apply forces on the material. At each specific piston speed, the rheometer calculates shear rate based on the capillary die geometry. As a result, it is important for the operators to use an appropriate type of the die which provides the desired testing condition for any specific material or application.

Dynisco provides various types of capillary dies with different diameters, lengths, and entrance angles. Each die has a specific part number as below where refers to the entrance angle, is the die dimeter in inches multiplying by 103, and is the die length to diameter ratio. The part number of each die can be found on the edge side of that die (image below)

Figure 1. The part number of a capillary die from Dynisco.

Die Entrance Angle

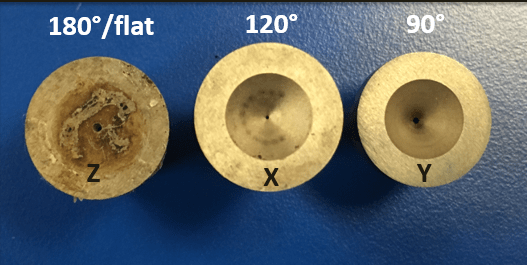

Entrance angle has effect on the flow patterns of melt at the entrance to the capillary die. Dies with lower entrance angle reduce the formation of re-circulating corner vortices as well as less unstable flow and energy consumption at the entrance of the die. Lower angle also favors shear flow and reduces the elastic deformation of the polymer melt. Dynisco provides capillary dies with entrance angles of 60° (W), 90° (Y), 120° (X), and 180° (Z). Figure 2 shows three dies with three different entrance angles.

Figure 2. Capillary dies with various entrance angles from Dynisco.

Figure 2. Capillary dies with various entrance angles from Dynisco.

Die Length

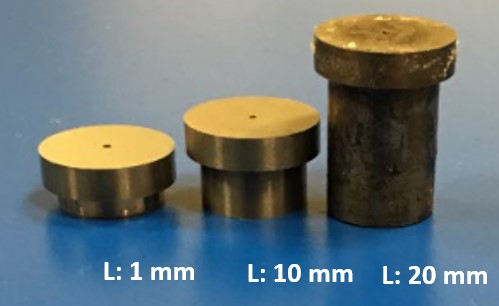

Dies with longer length produces less percent error which is produced by entrance pressure drop. In other words, the portion of fully developed flow inside the capillary die in compare with entrance region increases with increasing the die length. The reason is that viscoelastic polymer melts exhibit time dependency. As the polymer melts stay longer inside the die (using a longer die), the material forges the elastic deformation applied at the entrance of the die. A long die (L >15 mm) is suggested for measuring shear viscosity. A short die (L<15mm) however; is suggested for measuring elastic properties (e.g. die swell ratio, wall slip velocity, etc.). Figure 3 shows three dies with different lengths.

Figure 3. Dies with various lengths from Dynisco.

Die Diameter

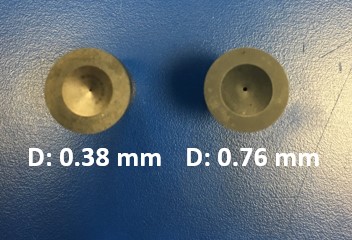

Die diameter has effect on the applicable range of the shear rates in the rheometer. Dynisco provides capillary dies with diameters ranging from 0.3 mm to 3.00 mm which enables the rheometer to produce shear rates ranging from 0.02 1/s to 277000 1/s. Normally, capillary dies with diameters of 0.75-1.5 mm provide the shear rates that matches with those from an extrusion or injection molding process. Dies with larger dimeter produces lower shear rates and reduces entrance pressure drop, slippage, extensional deformation, and die swell. Figure 4 shows two dies with different diameters.

Figure 4. Dies with various diameters from Dynisco.