In a world where AI is optimizing supply chains, robots are collaborating with people, and data drives every decision, the question is no longer if manufacturers should embrace smart maintenance—it’s how soon can you start?

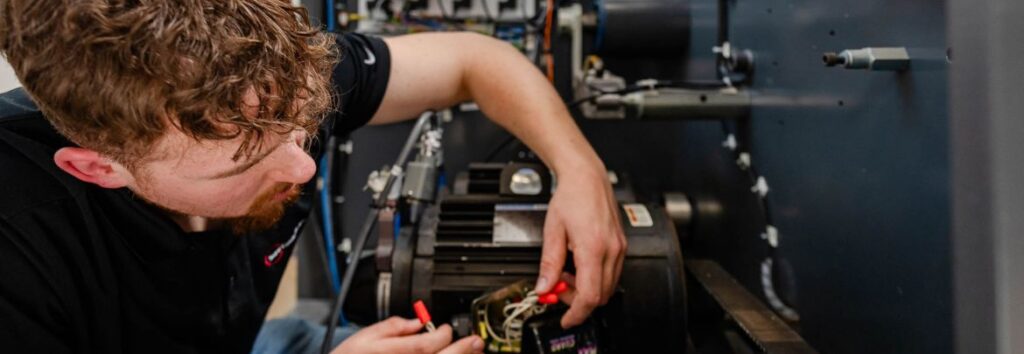

At Sure Controls, our Service Team is helping manufacturers transition from reactive firefighting to predictive, intelligent service models—because in today’s manufacturing landscape, traditional maintenance just doesn’t cut it anymore.

The High Cost of Waiting for Things to Break

Let’s be honest: reacting to failure is expensive. It slows production. It frustrates teams. It kills momentum. And worst of all, it’s avoidable.

In an Industry 4.0 world, machines can talk. Data is everywhere. AI is learning your production patterns better than any technician ever could. But if you’re not listening to that data—or worse, not collecting it—you’re stuck with blind spots that competitors are already eliminating.

Our Service Team has seen it time and again:

- Line shutdowns from worn components that showed signs weeks earlier

- Unplanned outages that could’ve been prevented with a single sensor

- Entire shifts lost waiting for parts that predictive analytics could’ve ordered in advance

What It Means to Have Sure Controls in Your Corner

When you partner with Sure Controls, you’re getting more than a service call—you’re gaining access to decades of expertise, cross-industry knowledge, and a team that’s committed to helping your operation run smarter.

Our technicians don’t just fix problems. They solve them at the root, and help prevent them from happening again. We work closely with your team to assess risks, plan regular service intervals, and install smart components that give you visibility into machine health.

“Only a few things are certain: death, taxes, and control system failure. Electrical controls won’t last forever, and some become obsolete way too fast, but that doesn’t mean you have to accept a painful future of downtime that exhausts your team and impacts your customers,” says Lance S., Sure Controls Service Team Supervisor. “We will help you build the bridge between what you have today and where you need to be to stay confident and competitive tomorrow.”

Where We Make the Most Impact

From food and beverage, paper and plastics to medical/life sciences, our customers rely on our service team to:

- Support seasonal production spikes with pre-checks and preventative adjustments

- Reduce scrap and waste by improving machine calibration

- Identify opportunities for automation upgrades during maintenance visits

- Extend the life of critical equipment through consistent care and smart retrofits

Ready to Shift from Reactive to Predictive?

If your facility is still relying on emergency service calls or outdated maintenance schedules, now’s the time to rethink your approach. Our team can help you build a roadmap to a more reliable, efficient, and data-driven maintenance strategy.

Let’s take the guesswork out of equipment health—together.

Connect with our service team today to get started.