In industrial manufacturing, electrical control panels serve as the critical nerve center for complex mechanical systems. They ensure that all electrical systems, devices, and machines are efficiently controlled, monitored, and protected. Without them, the manufacturing process can be chaotic and dangerous.

For these reasons, electrical control panel design, building, and assembly can be a complex process requiring attention to detail, planning, and expertise. This guide will take you through the essential steps needed to build and assemble an electrical control panel to control your manufacturing process and ensure safety and efficiency.

Planning and Designing

Before beginning any electrical control panel project, it’s essential to have a solid understanding of the manufacturing process and safety standards. This foundation allows you to design electrical schematics and panel layouts that cover all the key details, including power requirements, equipment specifications, signal types, and safety features.

The design should be customized to your manufacturing process needs and reviewed by your technical team to ensure functionality, ratings, and safety requirements are met. During the design review, it’s crucial to ensure that the control panel complies with all applicable Electrical Safety Standards, such as NFPA 70 (NEC), NFPA 79, or UL508A.

Whether you’re upgrading existing systems or starting from scratch, investing in the right control panel solutions can significantly impact operational efficiency and long-term reliability.

Physical Layout Considerations

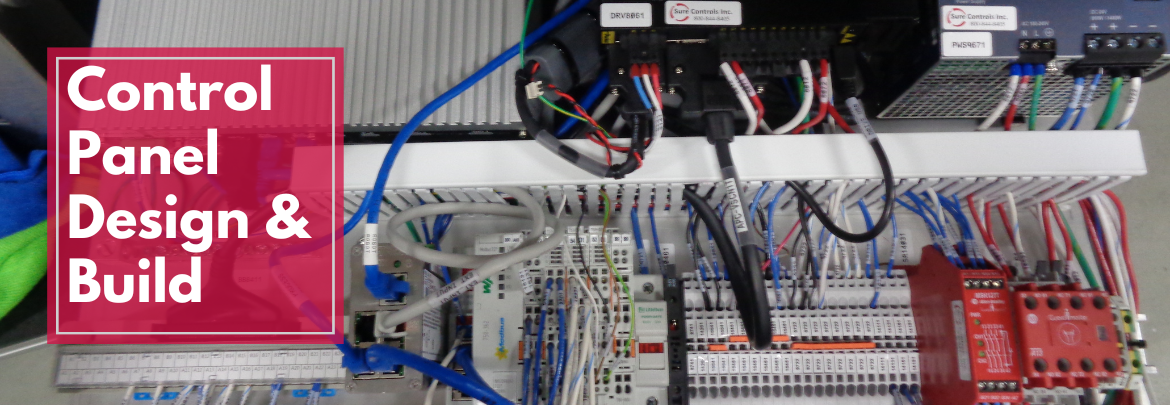

The physical layout of the control panel is another critical aspect of the design process. It involves determining the placement of essential electrical components, such as circuit breakers, terminal blocks, and power supplies, to ensure optimal airflow, accessibility, and compliance with spacing requirements.

Bill of Materials (BOM)

Developing a detailed bill of materials is also part of the planning phase. This document lists all required components, such as DIN rails, wiring ducts, relays, and programmable logic controllers (PLCs). A comprehensive BOM ensures you have everything needed for the project, saving time and reducing errors during assembly.

Assembling the Components

After finalizing the design, the next step is to gather and assemble all the required components for the control panel. Typically, control components are mounted on a subpanel, which is then installed in a panel enclosure. The electrical schematic design package provides detailed instructions on the required components and where they should be mounted on the subpanel.

Many control components are mounted on a standard-size DIN rail, which speeds up installation. Wiring ducts are also installed to allow clean wiring between devices. Manufacturers’ spacing requirements should be followed to ensure proper heat dissipation around components.

Along with mounting components on the subpanel, certain items like disconnect handles, air conditioners, push buttons, and stack lights will also be installed on the enclosure.

Control Devices and Integration

Modern control panels often include advanced control devices like human-machine interfaces (HMIs) and PLCs. These devices enhance automation and allow operators to monitor and control processes more efficiently. Proper integration of these devices is crucial for seamless operation.

Installation and Wiring

Once all the components are assembled, the next step is to wire the control panel based on the electrical schematic. The schematics will specify which terminal on each component the wire should be connected to, along with the appropriate wire gauge.

The wire color is also crucial because it indicates the voltage the wire carries, such as 24VDC, 120VAC, or 480VAC. Wire color must follow applicable standards. Additionally, each wire will be given a unique label. This ensures wires are landed properly and helps with future troubleshooting if issues arise.

Avoiding Short Circuiting

Proper wiring practices also help prevent short circuiting and other potential hazards. Ensure that wires are securely connected, insulated, and routed through wiring ducts to avoid accidental damage or contact with other components.

Testing and Quality Control

Once the control panel assembly and wiring are finished, the next step is to test and verify the electrical control panel. This step is essential to catch any wiring errors, confirm safety features are in place, and ensure everything is working correctly.

The first step is to check each wire for point-to-point continuity (also known as the “beep test”) against the electrical schematics to confirm that everything is wired correctly. This is an essential step before powering up the panel.

Once the beep test is complete, the panel can be connected to power and turned on to verify that all components are functioning properly. When working with a live panel, it’s important to prioritize safety by following standard safety protocols, such as lock-out tag-out and wearing gloves and eye protection.

Ensuring Quality Control Standards

A final checklist should confirm that the panel meets design criteria, such as proper grounding, the presence of informational or warning labels, and compliance with the required quality control standards.

Compliance and Certification

The final step is ensuring that your industrial control panel meets both local and national electrical codes and standards. If you’re unsure, it’s always a good idea to consult with a certified electrical safety inspector.

We recommend pursuing UL508A certification to confirm that your control panel complies with all necessary safety standards and regulations. This certification is essential for panels used in industrial environments, as it provides assurance of compliance and safety.

Documentation and Maintenance

Proper documentation is crucial for ongoing maintenance and troubleshooting. Include detailed wiring diagrams, test results, and a list of components to help electricians and electrical engineers service the panel in the future.

Common Challenges in Control Panel Design

Heat Management

Ensuring proper airflow and cooling is essential to prevent overheating. Use air conditioners, fans, and proper spacing between components to manage heat effectively.

Component Selection

Choosing high-quality components, such as durable terminal blocks, reliable circuit breakers, and efficient power supplies, ensures the longevity and performance of the control panel.

Safety Features

Incorporate safety features like emergency stops, overload protection, and surge suppressors to enhance operator and equipment safety.

Next Steps

Before choosing a panel shop, consider the following questions:

- Does my control panel need to be UL listed?

- Will I require detailed control panel documentation?

- How can I ensure compliance with the National Electrical Code (NEC)?

- What steps will I take to meet OSHA standards and improve operator and equipment safety?

- What are the specific spacing, safety, and efficiency requirements for this project, and how will I confirm they’ve been met?

At Sure Controls, we bring over 40 years of experience in designing and building industrial control panels. Our panels are highly organized, feature built-in diagnostic capabilities, and comply with UL, CSA, or CE safety standards. If you want to learn more, reach out to us at [email protected] or contact a team member by filling out a form on our website.

We are happy to answer any questions you might have.