MICRO-AUTOMATION

Micro-Automation Manufacturing Process

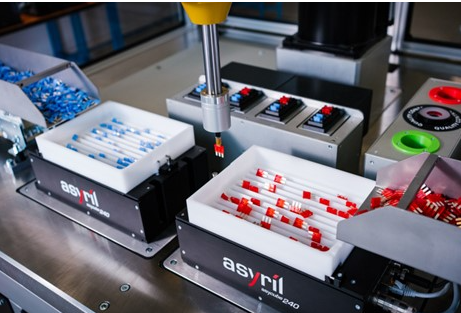

Precision Meets Efficiency in a Compact Footprint

At Sure Controls, we specialize in micro-automation solutions that deliver big results in small spaces. Our approach combines advanced robotics with flexible feeding technology to seamlessly handle small, lightweight components—typically under 6 inches and 2 pounds—with unmatched precision, speed, and reliability.

Whether you’re streamlining delicate assembly tasks or scaling high-mix, low-volume production, micro-automation bridges the gap between manual handling and full-scale automation—helping you boost throughput, improve quality, and maximize floor space.

Custom Micro Automation in Action

This aerospace and defense application showcases the power of our precision micro automation solutions—from the delivery of a 16-foot tube to laser wire cutting with zero internal debris. Vision guidance, customizable HMI, and integrated safety features make this solution a standout example of Sure Controls engineering in motion.

Benefits of Micro-Automation Solutions

Lower Overall Investment

- Complete cells can be re-purposed with simple cost-effective End Of Arm Tooling (EOAT) changes and recipe changes

- No need to purchase new capital (part feeder) to run different parts

Added Flexibility (one cell can handle multiple parts)

- One of our customers is running 1000+ part numbers on the same cell

Quick Changeover

- Custom trays can be designed for nesting of parts with changeover in minutes vs. hours

Automate Where Not Previously Possible

- Part orientation for assembly with vision guided picking

- Spring detangling

Reduced Manufacturing Real Estate (on average 30-50%)

- Integrate multiple processes (feeding, handling, assmebly) into a single footprint

- Eliminates the need for multiple large machines or manual workstations

Flexible Collaborative Systems

Enhance efficiency with Sure Controls’ flexible collaborative systems. As the need for modularity and adaptability in automation grows with shorter production runs and lower volumes, our team can collaborate with yours to design a solution that meets your current needs while being cost-effective and easily adaptable for future products. Learn more about our flexible collaborative systems today.

What is Micro-Automation?

Micro-Automation is automating a manufacturing process that involves handling small parts. Small part is defined differently for each customer, but for Sure Controls that ranges anywhere from 6 (150mm) inches on the large side down to .2 inches (5mm) and typically less than 2 pounds.

3-Axis Flexible Part Feeding Solution

There are many factors to take into consideration when approaching system automation. These may include: product in-feed, product out-feed, cycle rate, and quality inspection. Perhaps the most important factor is a clear definition of success and a shared vision on how to reach it. Sure Controls values these partnerships. Your success is our success.

Applications that involve handling small parts “micro-parts” introduce an additional level of complexity. This is due to challenges in handling the parts on the in-feed side. Traditionally, the in-feed of parts into an automation cell is done with products like a bowl feeder. Bowl feeders have limitations including: changeover (each bowl feeder is designed for a specific part), high investment that can’t be easily re-purposed, difficulty handling delicate material, jamming and part re-circulation.

Affordable Micro-Automation

At Sure Controls we want to offer our customers the best solution for their application requirements. This is why we offer Aysril, and Mecademic micro-automation robotic solutions. For example, Asyril has a 3-axis vibration “Asycube” flexible part feeding solution that is easily integrated into robotic automation cells.

Not only do we sell these products but we work to create the best possible solutions by integrating these products into your set up. This may mean a product or a solution that includes an Asyril robot and a Mecademic robot working together. Our robotic integration designers can help customers automate in areas where, in the past, it may not have been economically or technically feasible.

Integrating Flexible Part-Feeders

Sure Controls has successfully provided systems in the electronics, medical, automotive, and plastics industries with the integration of flexible part-feeders. In each of these markets, we were able to introduce a technology that allowed the customer to improve the automation cell or entirely rethink how they could better automate, allowing them to secure new business opportunities.

At Sure Controls we define success by delivering smiles. It’s that simple, when we deliver a solution our customers need, we leave them smiling.

At Sure Controls we define success by delivering smiles. It’s that simple, when we deliver a solution our customers need, we leave them smiling.