What is the difference between and a resistance temperature detector (RTD) and a thermocouple?

What is the difference between and a resistance temperature detector (RTD) and a thermocouple?

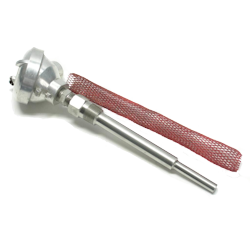

Resistance Temperature Detectors (RTDs) and thermocouples are two of the most widely used temperature-measurement technologies in industrial environments. Both function as temperature sensors, but they rely on different principles and offer distinct performance characteristics. RTDs, including common types such as PT100 elements, measure temperature through the predictable change in resistance within a metal conductor. Thermocouples generate a voltage signal created by the junction of two dissimilar metals.

Understanding how an RTD sensor compares with a thermocouple helps determine which option is best suited to the required accuracy, temperature range, and installation conditions.

Resistance Thermometer Detectors

The electrical resistance of metals rises as heat increases and the metals become hotter, while their electrical resistance falls as heat decreases and the metals become colder. RTDs are temperature sensors that use the changes in the electrical resistance of metals to measure the changes in the local temperature. For the readings to be interpretable, the metals used in RTDs must have electrical resistances known to people and recorded for convenient reference. As a result, copper, nickel, and platinum are all popular metals used in the construction of RTDs.

The most prevalent configuration, the PT100 RTD, is defined by having 100 ohms of resistance at 0°C and provides a highly linear and predictable response.

RTDs are available in multiple wiring formats, often referred to as two-wire, three-wire, or four-wire RTD line configurations, allowing the sensor to compensate for lead-wire resistance depending on installation requirements.

Thermocouples

Thermocouples are temperature sensors that use two different metals in the sensor to produce a voltage that can be read to determine the local temperature. Different combinations of metals can be used in building the thermocouples to provide different calibrations with different temperature ranges and sensor characteristics.

Their simple construction and broad compatibility make them a common alternative to RTD temperature sensing where extreme conditions are present.

Download the Sure Controls thermocouple design sheet for more information.

RTD vs Thermocouple

Because the terms encompass entire ranges of temperature sensors tailored for use under a range of conditions, it is impossible to conclude whether RTDs or thermocouples are the superior option as a whole. Instead, it is more useful to compare the performance of RTDs and thermocouples based on key qualities, such as cost and temperature range, so users can choose based on their organization’s specific needs.

In general, thermocouples are better than RTDs when it comes to cost, ruggedness, measurement speed, and the range of temperatures that can be measured using them. Most thermocouples cost 2.5 to 3 times less than RTDs and although RTD installation is cheaper than thermocouple installation, the savings in installation costs are not enough to tip the balance. Furthermore, thermocouples are designed to be more durable and react faster to changes in temperature because of that same design. However, the main selling point of thermocouples is their range. Most RTDs, including common PT100 configurations, are limited to a maximum temperature of 1000 degrees Fahrenheit. In contrast, certain thermocouples can be used to measure up to 2700 degrees Fahrenheit.

RTDs are superior to thermocouples in that their readings are more accurate and more repeatable. Repeatable means that users reading the same temperatures produce the same results over multiple trials. RTDs producing more repeatable readings means that their readings are more stable, while their design ensures that RTDs continue producing stable readings longer than thermocouples. Furthermore, RTDs receive more robust signals and it is easier to calibrate RTD readings due to their design.

Conclusion

In brief, RTDs and thermocouples each have their own advantages and disadvantages. Furthermore, each type of RTD and thermocouple has its own advantages and disadvantages. Buyers should base their purchasing decisions on the specific needs and capabilities of their organizations, matched to the specific capabilities of the brands available to them. In general, thermocouples are cheaper, more durable and can measure a bigger range of temperatures, while RTD sensors produce better and more reliable measurements.

Have questions? Fill out our contact form and a skilled Sure Controls professional will be in touch.

Check out all of our thermal sensors

Looking For Industrial Automation Parts? We Can Help!